Polypropylene (PP) Air Conditioning and Ventilation Ducts

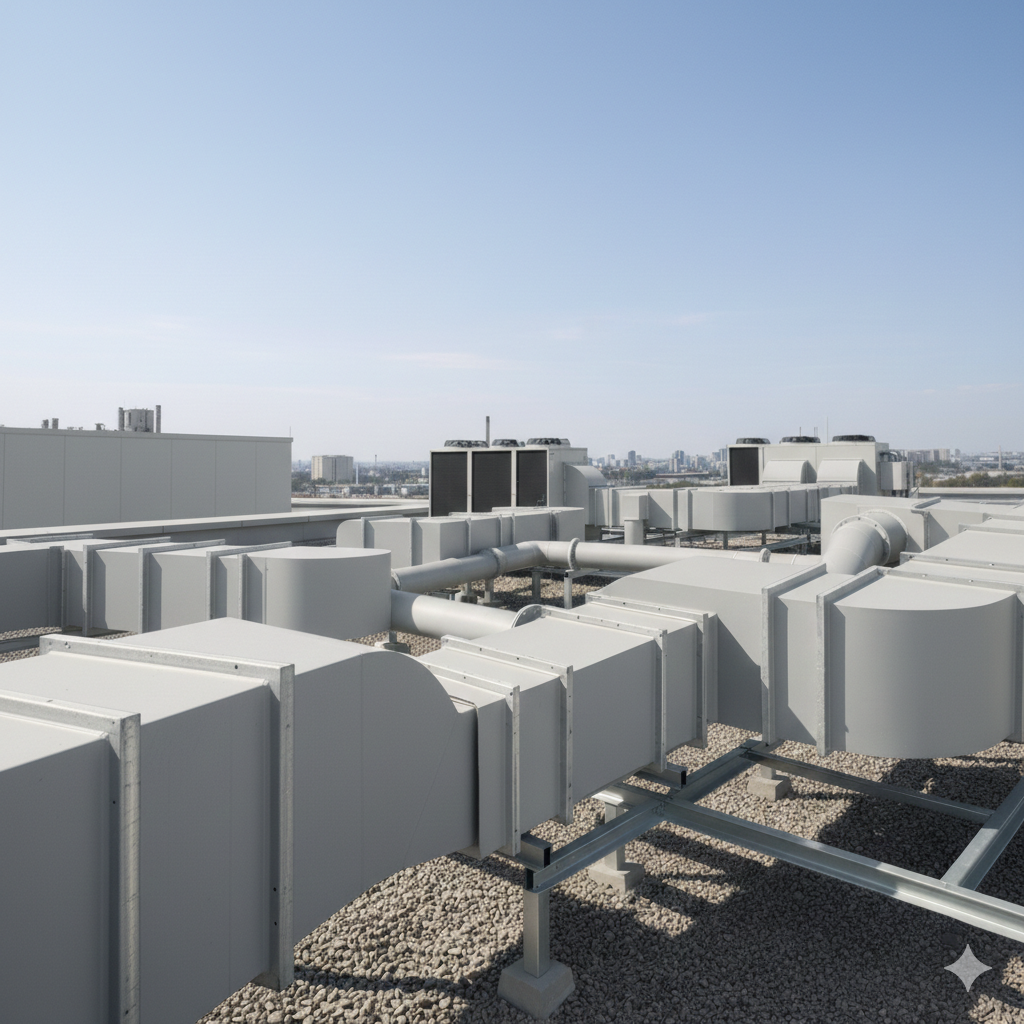

Polypropylene (PP) air conditioning and ventilation ducts are designed for industrial HVAC systems operating in demanding environments where vapors, gases, and corrosive chemical substances are present. The ducts are manufactured from high-quality thermoplastic materials with excellent chemical resistance, providing a reliable, safe, and long-term solution for conveying clean or contaminated air in industrial facilities.

Thanks to the combination of resistance to acids and alkalis, low weight, and full engineering flexibility, polymer duct systems offer an advanced alternative to metal ducts in environments requiring high resistance to corrosion and humidity.

Key Advantages

-

Exceptional chemical resistance to acids, alkalis, and aggressive gases

-

Ideal solution for industrial air conditioning and ventilation systems

-

Lightweight construction for easy installation and suspension

-

Smooth internal surfaces for efficient airflow and reduced contaminant buildup

-

No rust, no corrosion, and no need for protective coatings

-

Long service life, even under harsh operating conditions

Range of Materials According to Project Requirements

In addition to polypropylene (PP), air conditioning and ventilation ducts can also be manufactured from other thermoplastic materials, depending on the process conditions, temperature, and conveyed media:

-

PP-R / PPR – Suitable for higher temperature systems and advanced industrial applications

-

PP-H (PPH) – Higher rigidity and improved pressure resistance

-

HDPE – Excellent resistance to mechanical impact and outdoor environments

-

Other polymeric materials – According to specific chemical and engineering requirements

Material selection is performed following a full engineering evaluation of the operating conditions.

Typical Applications

-

Ventilation and extraction systems in chemical processing plants

-

Industrial HVAC systems

-

Conveyance of process vapors, acid fumes, and gases

-

Fume hoods and extraction systems

-

Pharmaceutical, food, fertilizer, metal processing, and surface treatment plants

Technical Characteristics

-

Material options: PP / PPR / PPH / HDPE

-

Operating temperature range: up to approx. 90°C (depending on material and design)

-

Diameters, wall thicknesses, and shapes: custom-designed per project requirements

-

Jointing methods: thermal welding / extrusion welding

-

Standard color: grey PP (custom colors available)

Project Integration

Polymer HVAC and ventilation ducts are manufactured according to engineering drawings and system design requirements. They can be integrated into existing systems or supplied as part of new projects, with full adaptation to airflow rates, pressures, and installation constraints.